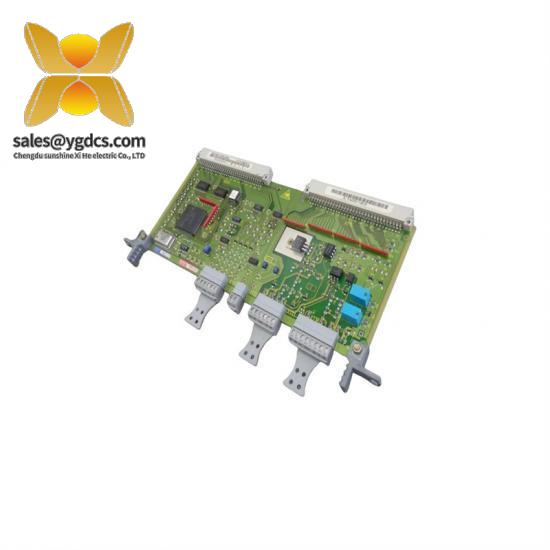

Siemens 6SE7090-0XX84-0BA0 MASTERDRIVES Digital tachometer & synchronization module

This Siemens Digital Tachometer and Synchronization Module offers precise RPM measurement and synchronization capabilities for industrial automation applications.

Email:18005021035@163.com

Phone:+86 18005021035

Name:BeiLin

Content details

Application Area:Industries requiring high accuracy speed measurement and synchronization

Module Type:Digital Tachometer & Synchronization Module

Manufacturer:Siemens

Model Number:6SE7090-0XX84-0BA0

Operating Range:0 Hz to 400 Hz

Resolution:1 μm

Accuracy:+/- 0.05%

Operating Temperature:-20°C to +60°C

Power Supply Voltage:24 V DC

Communication Interface:Profinet, EtherCAT

Dimensions (WxHxD):140 mm x 100 mm x 90 mm

Weight:1 kg

This state-of-the-art module from Siemens is engineered for unparalleled performance in demanding industrial environments. Its compact design ensures minimal interference and efficient installation, while its robust construction withstands harsh conditions, ensuring longevity and maintenance-free operation.

Equipped with advanced signal processing capabilities, this module accurately measures both speed and direction, providing real-time feedback essential for complex machinery operations. Its compatibility with Profinet ensures seamless integration with existing industrial networks, enhancing operational efficiency.

The Siemens 6SE7090-0XX84-0BA0 module is ideal for applications requiring precise measurement and synchronization, such as in the manufacturing of metals, textiles, and automotive components. Its ability to withstand extreme temperatures makes it suitable for outdoor or high-temperature industrial settings.

Installation and maintenance are straightforward, thanks to intuitive programming and user-friendly interface. Comprehensive documentation and support ensure a smooth onboarding process for users, minimizing downtime and maximizing productivity.

By leveraging the latest technology in digital tachometer and synchronization, this module optimizes energy usage and reduces wear and tear on equipment, leading to cost savings and improved overall system performance.